Turn Potential Into Profit

Completed Projects

| PSDP Projects Implemented by SMEDA | ||||

| Sr. | Project Name | Location | Cost (Rs. Million) | Objectives |

| Completed Projects | ||||

| 1 | National Business Development Programme for SMEs | All Pakistan | 1954.978 | The project aims to provide support to SMEs support mechanisms for handholding of SMEs to undertake an important role in the global market by increasing export capacities of SMEs, providing access to valuable information, developing networks and promoting internationalization and innovation in SMEs. |

| 2 | SME Business Facilitation Center | Multan | 59.89 | Objective of the project is to facilitate local SMEs by extending business development support to them. |

| 3 | Agro Food Processing Facilities (AFP) | Multan | 207.73 | A common facility center for pulp extraction of various fruits in Multan and value addition of products by introducing fruit and vegetable processing techniques. |

| 4 | Gujranwala Business Centre (GBC) | Gujranwala | 98.78 | A Business Infrastructure facility to provide a single promotional and display platform for a range of products manufactured in Gujranwala in order to attract national and international buyers. |

| 5 | Washing & Pressing Unit | Matta Mughal Khel, Charsadda | 5.38 | To provide professional Washing/Dry Cleaning & Pressing facility to weavers to improve quality of cloths and value addition. |

| 6 | Chromite Beneficiation Plant | Khanozai | 24.66 | A Common Facility Center to enrich Chromite content of the ore, liberate it from unwanted impurities eventually separate the final product into uniform grain sizes. |

| 7 | Women Business Incubation Center (WBIC) | Lahore | 59.59 | To provide a secure facility (office space, product display facility, business consultancy, training and networking) for women entrepreneurs in Lahore promoting especially home based business to move out. |

| 8 | Women Business Development Center (WBDC) | Peshawar | 28.41 | The purpose of establishing the Business Development Centre for women is to accelerate the successful development of female entrepreneurs by providing them with an array of resources and services. |

| 9 | SME Subcontracting Exchange | Gujranwala | 26.09 | SMEs competitive through inter-firm linkages, promoting large manufacturing to procure/subcontract from small firms. |

| 10 | Revival of Cutlery Institute of Pakistan | Wazirabad | 39.84 | Improving craftsmanship skills by conducting short term/long training programmes for semi-skilled persons and BMR/Up-gradation of presently available Common Facility Center |

| 11 | Revival of Hyderabad Leather Footwear Center (RHLFC) | Hyderabad | 58.893 | The purpose of this project is to revive Hyderabad Leather Footwear Center (HLFC) and train workers from footwear cluster of Hyderabad in modern machine made shoe making |

| 12 | Glass Products Design & Manufacturing Center (GPDMC) | Hyderabad | 59.27 | To diversify the bangles manufacturing cluster into manufacturing other glass products & to introduce more suitable techniques and technology into the industry. |

| 13 | Policy & Project Implementation, Monitoring & Evaluation Unit (PPIM&EU) | Lahore | 25.82 | The objective of the project is to oversee implementation of the SME Policy & PSDP funded projects undertaken by SMEDA. |

| 14 | Sports Industries Development Centre (SIDC) | Sialkot | 435.637 | A Common Facility Center with the objective to help introducing mechanized ball technology in soccer ball industry, Sialkot. |

| 15 | Sialkot Business & Commerce Center (SBCC) | Sialkot | 312.94 | Provision of business infrastructure facility for exporters especially SMEs and strengthening partnership with local industry. |

| 16 | Foundry Service Centre (FSC) | Lahore | 206.31 | First institutional set up to support foundry cluster, Product Dev. Support i.e. Light Engg. Sectors, Casting process optimization, Compliance with Int’l quality standards and new technology integration, Training, Consultancy & Advisory services for SMEs. |

| 17 | Women Business Development Center (WBDC) | Karachi | 58.84 | To provide a secure facility (office space, product display facility, business consultancy, training and networking) for women entrepreneurs in Karachi promoting especially home based business to move out. |

| 18 | Women Business Incubation Center (WBIC) | Quetta | 58.08 | The major goal of this project is to help women to develop their business skills that will enable them to compete effectively in today's marketplace. |

| 19 | CTFC for Light Engineering Cluster | Mardan | 39.98 | The major objective of the project is to increase manufacturing capacity of the region to produce high quality Agri implements and tools. |

| 20 | Establishment of Spinning CFC-Islampur | Swat | 29.697 | To provide the cluster with innovative methods of wool spinning resulting in cost reduction and time saving. To provide support to the cluster activities to improve their product quality enhancing local demand and bringing them to international standards for export. |

| 21 | Establishment of CFC for Silk Cluster | Swat | 57.53 | To improve quality of silk cloth by provision of Dyeing, Washing and Pressing plant as a common facility in the cluster. |

| 22 | Establishment of CFC for Honey Processing and Packaging | Swat | 38.17 | To provide proper Honey Extracting & Processing facilities, Honey Cleaning and Packing facility to the Honey Bee Farmers, Honey traders and Honey exporters at their doorstep. |

| 23 | Women Business Development Center (WBDC) | Swat | 35.01 | The establishing the Women Business Development Centre, Swat will accelerate the successful development of women entrepreneurs and promoting an entrepreneurial culture amongst women in Swat. |

| 24 | Red Chilies Processing Center (RCPC) | Kunri | 244.7 | To Introduce & demonstrate mechanical dehydration of chilies and to Improve quality of dried chilies |

| 25 | SMEDA SME Facilitation Complex at PITAC | Lahore | 57.2 | Facilitation of Business Development Services to SMEs |

| 26 | Spun Yarn Research and Development (R&D) Company (SYRDC) | Multan | 59.75 | The project would enhance the competitiveness of ginning and spinning industry of the region and aims to consume waste of cotton spinning industry to convert it into valuable market product. |

| 27 | Leather Crafts Development Company (LCDC) | Multan | 214.01 | Add value, on modern footings, in traditional craftsmanship of leather products sector and enhancing competitiveness, efficiency, quality and productivity of sector in Southern Punjab |

| 28 | Khadi Crafts Development Company (KCDC) | Multan | 230 | To revive traditional craft of Khadi industry sector and enhancing competitiveness and Productivity of Khadi Industry in Southern Punjab |

| 29 | Juice Producing and Packaging Line for Fresh Fruits and Vegetables | Multan | 59 | Improve the market share of the local fruit and vegetable juices by utilizing efficient marketing practices |

| 30 | Fruit Dehydration Unit | Swat | 59.94 | The objectives of the Fruit Dehydration Unit, Swat to support the fruit growers in product diversification and value addition and introduce modern technology for bulk production of hygienic products, so that the existing marginalized processors can meet the international standards. |

| 31 | Agro Food Processing Facilities (AFP) | Mirpurkhas | 960.318 | Project aims to provide the processing/value addition facilities for pulp extraction of various fruits like Mango, Guava, Strawberry and Tomato Paste/puree etc. AFP MirpurKhas will be established as a Common Facility Center for fruits/vegetable grading & pulping to farmers and traders to facilitate trade of processed value added fruits & vegetables. |

Ongoing Projects

| PSDP Projects Implemented by SMEDA | ||||

| Sr. | Project Name | Location | Cost (Rs. Million) | Objectives |

| Ongoing Projects | ||||

| 1 | Product Development Center for Composites Based Sports Goods | Sialkot | 487.97 | Product Development Center for Composites Based Sports Goods is a project to facilitate in increasing exports of composites based sports goods, prototype production, provide skilled workforce to the sector, product testing (physical and chemical), help in development imported machinery locally, and enhance productivity by providing technical consultancy services to new and existing industrial units. |

| 2 | Business Skill Development Centers for Women | Dera Ismail Khan | 59.493 | The establishing of Business Skill Development Center will accelerate the successful development of women entrepreneurs and promoting an entrepreneurial culture amongst women in Dera Ismail Khan. |

| 3 | 1000 Industrial Stitching Units | All Pakistan | 350.545 | Projects aims to boost the value addition in the field of textile garments by establishing “Industrial Stitching Units” across the country. The aim of the project is to financially support the Small and Medium Enterprises of textile including both existing and new entrepreneurs. |

| 4 | Research, Regulatory Insight & Advocacy Assistance for SMEs | Lahore | 200 | The project will facilitate Government of Pakistan in developing evidence-based policies for SME development in the country to increase ease of doing business and simplify regulatory regime/ procedures to ensure facilitation to new as well as existing businesses. |

| 5 | Acquisition of land for Establishment of SME Facilitation Centers at Various Locations | Lahore, Karachi, Peshawar & Quctta | 1250 | SME Business Facilitation Center will serve as one-stop-shop to provide business development services, incubation and training services. The Center will comprise of: 1. SME Training Institute (SMETI) 2. SME Incubation Center (SMEIC) 3. Women Business Development Center (WBDC |

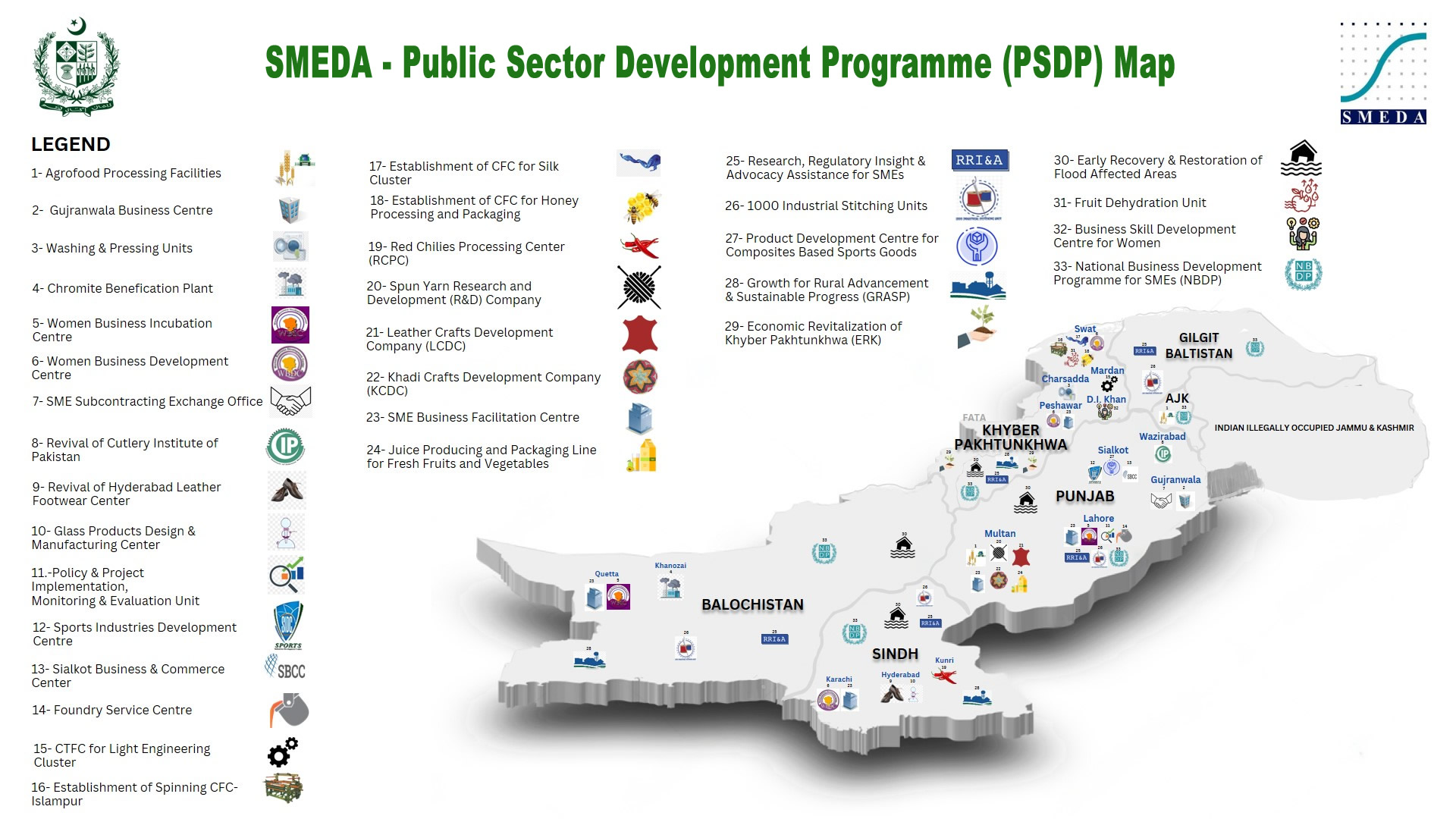

Public Sector Development Programme (PSDP)

(click to enlarge the map image)

(click to enlarge the map image)

SMEDA stepped into the foray of the Public Sector Development Program (PSDP) in 2006-07 by initially establishing four Common Facility Center projects, financed through the PSDP window. These projects are conceived in consultation with prominent cluster stakeholders and aim to catalyze the adaptation of best business practices and induction of new technologies through demonstration, training, provision of common facilities, and ancillary services. Currently, SMEDA has a portfolio of twenty-eight projects with a total outlay of Rs. 4.2 Billion.